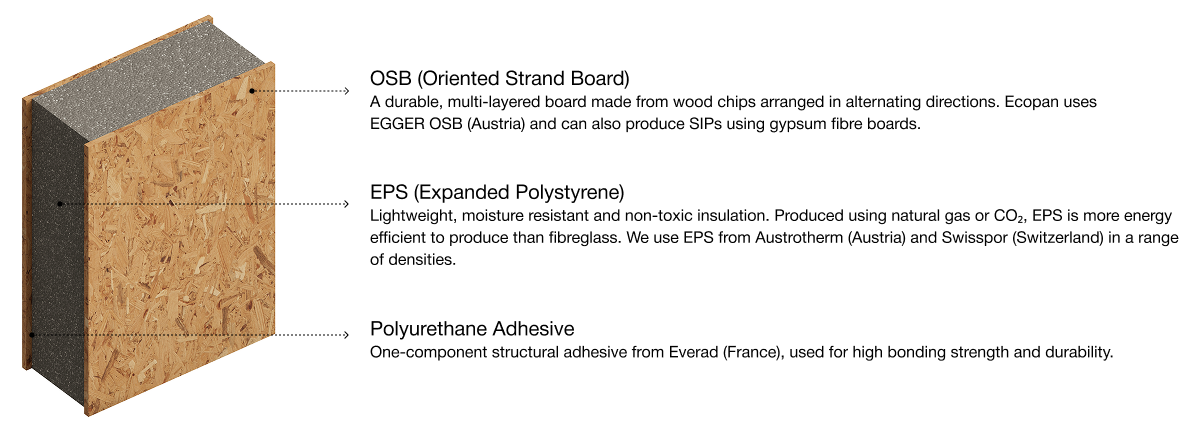

ECOPAN manufactures SIP panels at a modern factory in the EU (Romania), providing a full production cycle – from material selection to packaging and delivery. We use only certified components from leading European brands: OSB EGGER (Austria), EPS insulation from Austrotherm and Swisspor, and French polyurethane adhesive Everad.

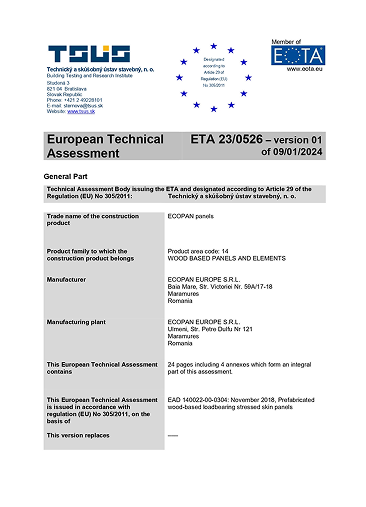

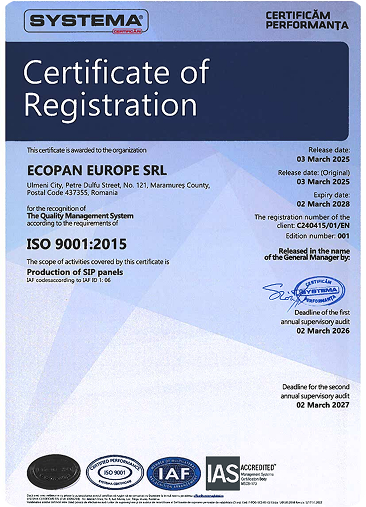

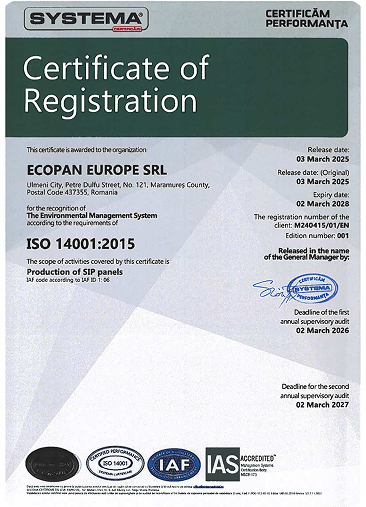

Thanks to precise automated processing, our SIP panels demonstrate high energy efficiency, stable geometry and a long service life. Each panel undergoes a multi-level quality control to ensure compliance with European construction standards ETA, CE, ISO 9001 and EN 1364.

ECOPAN’s production facilities allow us to implement projects of any scale: from individual housing to mass construction. We also manufacture SIP panels to order – with individual dimensions, cladding type and packaging.